Interactive point of sale for consumer electronics products

Behind the scenes showing how we build our interactive displays.

- DESIGN & PROTOTYPING

- LOCAL MANUFACTURING

- LIGHTING, VIDEO AND SOUND

- SUITABLE FOR ALL RETAIL STORES

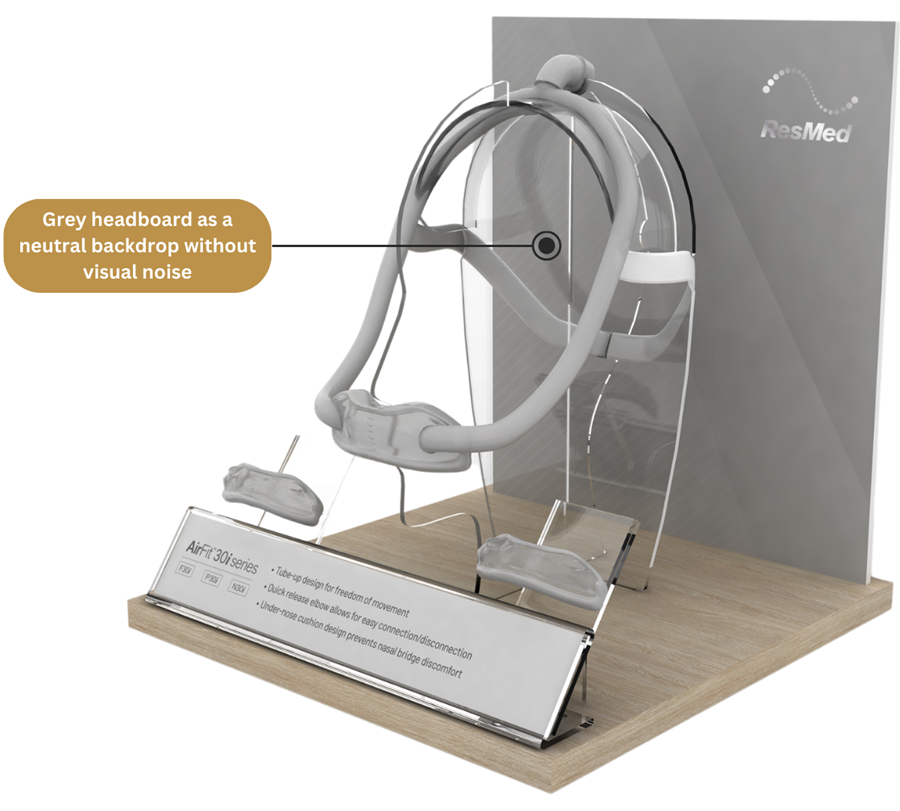

CONCEPT IDEAS

As specialists in custom point of sale design we have built up a wealth of experience creating interactive point of sale displays for products in Australian retailers. As you have seen in the video the process is quite extensive with a lot of detail put into each project.

Interactive displays can increase conversion rates by more than 100% as shoppers can touch, feel and listen to products in a store before buying.

One of the first steps of course is turning a brief into concept ideas to try and present solutions that can solve the retail display solution needed and enable the custom point of sale design process to begin. Our team can create a number of options for consideration that can be taken to brand or product managers for approval so that creative ideas can be explored easily.

These can include;

– Video

– Lighting

– Sound

design & prototypes

Once a concept has been agreed on we start working on the actual design and prototyping to ensure we can construct an interactive display using a mix of materials and electronics. We will even make sure things like security and OH&S are considered.

In most examples we spend a lot of time integrating electrical circuitry with devices, audio or lighting to bring a product to life on shelf.

CASE STUDIES

In the video we showcase the creation of the Ultimate Ears bluetooth speaker display stand which we have also featured as a more detailed Case Study

MANUFACTURING & DISTRIBUTION

In this video we are creating the interactive displays for Ultimate Ears bluetooth speaker range where our first step is with the chassis of the display. We assemble some of the mounting components then the audio components that go into the display which is their bluetooth speaker range.

This type of custom point of sale manufacturing in Sydney can take about two hours of concentrated work per unit. Once a unit is constructed we then make sure it is cleaned and tested to make sure everything is working as expected.

Once the unit has passed all our checks it is sent to the packaging stage. We make sure the displays are put into robust packaging to reduce potential damage and minimise any failure rates. We also include instructions with photos rather than line drawings, so the field teams can follow those nice and easily.

RETAIL SET UP AND INSTALLATION

Most brands will then organise to have their retail merchandising team visit each store to get the units installed and working properly.